We’ve spent a great deal of time talking about battery metals and electric vehicles (EVs) here at Equity.Guru of late. The E-Mobility (Electro Mobility) supercycle, for nearly every conceivable mode of transport, appears to be taking on a life of its own.

Soon, EV drivers will dominate our roadways.

Of course, there will always be killjoys – some people just aren’t joiners.

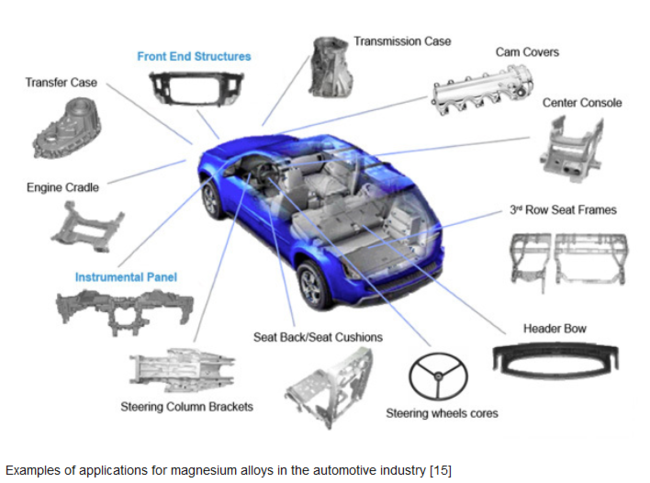

In our coverage, we’ve discussed many of the vital components that go into the lithium-ion battery, and the EV itself. We’ve talked about copper, cobalt, lithium, and graphite.

But what about magnesium?

Magnesium is being called the “Metal of the Future.”

They ain’t just whistling Dixie with this lofty designation. Magnesium (Mg) has some compelling properties:

- a very high strength-to-weight ratio

- an equally high stiffness-to-weight ratio

- the best machining properties of all metals

- a high vibration dampening capacity (great for when speed is involved)

- high dent resistance

Get this: Magnesium is 75% lighter than steel, and 33% lighter than aluminum.

Magnesium alloys are 48-78% lighter than steel and 22-35% lighter than aluminum.

Lighter frames and components mean greater energy efficiency in a vehicle.

Reducing the weight of a gasoline-powered car by 10% will result in a 6-8% fuel economy improvement.

Using lightweight materials in EVs can offset the weight of power systems such as batteries and electric motors, improving the efficiency and increasing the driving range.

These lightweight materials could also mean smaller and lower cost batteries while keeping the driving range constant.

Hmmm… all of this talk about light-weighting EVs – seems like a no-brainer to this humble observer.

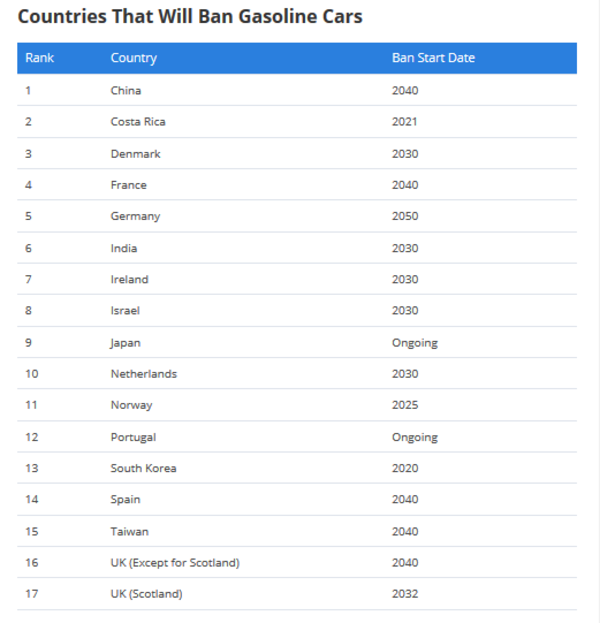

On the subject of EVs, yes, the push is most definitely on…

As the E-Mobility supercycle intensifies – as more and more countries seek to rid their highways and byways of fossil fuel powered cars – the demand for magnesium is destined to soar.

There’s also this…

This potentially disruptive new technology is a topic best left for another day.

This is why magnesium is being called the “Metal of the Future.” It’s not just a slogan.

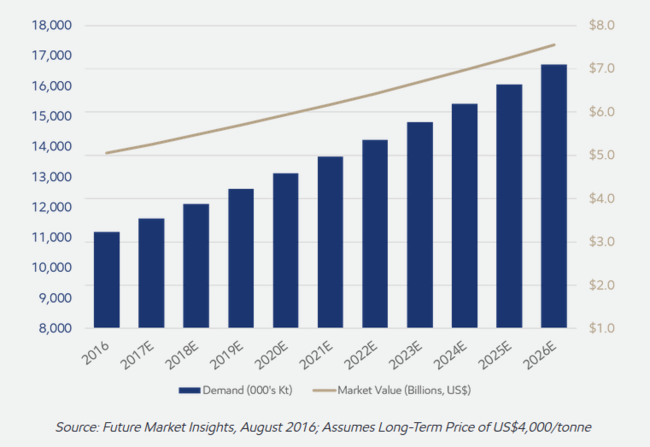

Supply/Demand

Efficiency targets set by the auto industry will require roughly 100 pounds of magnesium going into each new vehicle by 2025.

Global primary magnesium demand is expected to increase by 5.0% annually reaching 1.58 million tonnes by 2027.

There could be serious issues on the supply side of things.

Last May, the US Department of the Interior named 35 minerals critical to national security. Magnesium made the list.

China is the world’s top producer, accounting for roughly 66 percent of global output. With tariff and trade wars in full-on escalation mode, new, domestic sources of the metal need to be delineated and developed.

Enter Mag One…

Mag One Products (MDD.CN)

43.44 million shares outstanding

$4.34M market cap based on its recent $0.10 close.

Mag One is a technology, processing & production company. Using our game-changing technology, Mag One aims to be the most environmentally friendly & sustainable producer of magnesium metal, ultrapure Mg compounds, by-products and vertically integrated co-products.

There are a lot of moving parts to this company. We’ll give you a broad stroke in this piece, and expand further in subsequent offerings.

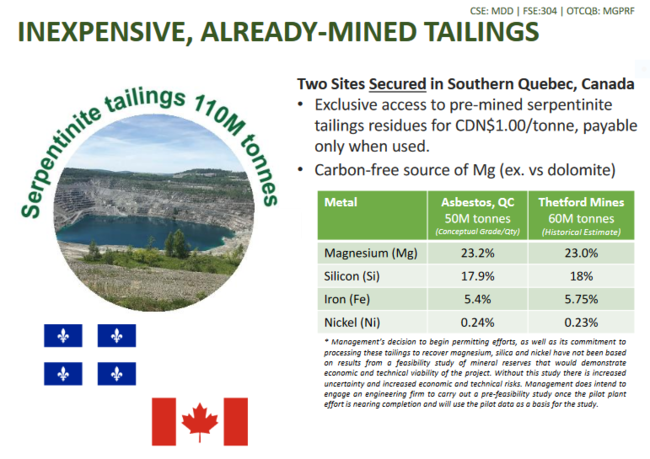

Mag One’s fundamentals begin with two highly strategic resources located in mining friendly Quebec.

Note that these resources deemed conceptual and historical. Having said that, note the grades on the slide below.

Separate agreements have been struck for exclusive access to tailings piles from two sites, one in Asbestos, the other in Thetford Quebec.

Tailings piles?

Tailings are waste rock left over after ore is mined, crushed, and stripped of its desired mineral. Here, the desired mineral was asbestos.

In most cases, this barren waste rock is dumped near the active mine. As the tailings pile up, they take the form of small mountains of weakly consolidated material completely devoid of vegetation.

My understanding is that these particular tailings piles are visible from outer space.

Decades of asbestos production created vast quantities of tailings – the foundation of Mag One’s magnesium resource.

The advantage here is clear. The magnesium is sitting right at surface, in giant piles of loosely consolidated material, just waiting to be hauled off by truck for processing and development.

It doesn’t get any easier than that.

Speaking of processing and development…

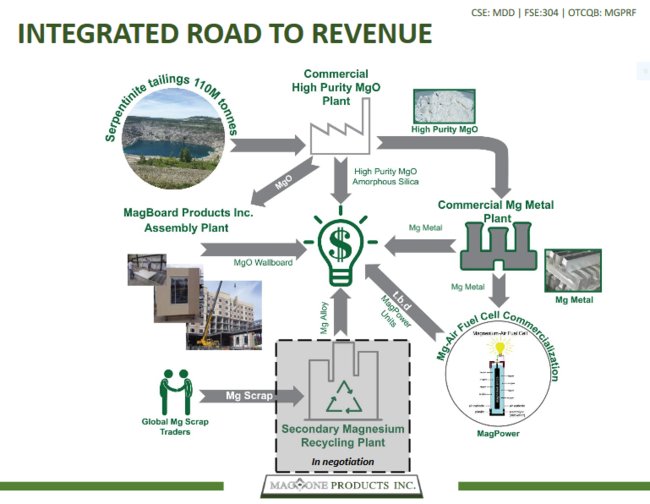

Mag One’s sights are set on becoming a global leader in the magnesium arena by concentrating on four areas:

- Production of high-purity MgO, silica and other saleable co-products, byproducts and compounds.

- Production of 99.9% pure Mg ingots.

- Magboard Products Inc., assembly and sale of MgO-based, structural insulated sheathing panels and wallboards.

- MagPower’s Mg-Air Fuel Cell for scalable emergency power on sea and land.

Note that this is a environmentally friendly, low carbon footprint, (virtually) zero waste process.

Mag One’s project page:

Recent milestones

Back in Jan of this year, the company inked an agreement with Tech Magnesium.

Mag One Concludes Technology Acquisition Agreement with Tech Magnesium

This deal paves the way for the acquisition of a silicothermic and aluminothermic reduction process for low cost, environmentally-friendly production of primary magnesium metal.

“The Agreement outlines three phases of development and demonstration work with the final phase involving the design, construction and start-up of Mag One’s first 5,000 tonne per year primary Mg metal module with additional modules being brought online to coincide with market demand. During the term of the Agreement Mag One has an exclusive, worldwide license to the Tech Mag Technology as well as the exclusive right to acquire full ownership of the Tech Mag Technology and all associated intellectual property.“

Then in March, the company dropped news that the National Research Council of Canada (NRC), under its Industrial Research Assistance Program (NRC-IRAP), had approved Mag One’s project:

The NRC will support the project, entitled Feasibility – Magnesium Production using Aluminothermic Reduction Process, contributing on a cost-sharing basis. The program is expected to conclude during the summer of 2019.

“… this NRC-IRAP-funded Project represents the first phase of the development and demonstration work towards the low cost, environmentally-friendly production of primary magnesium metal.”

The project development phases

The project will consist of thermodynamic modeling, bench-scale experiments, process optimization, and techno-economic analysis.

Magnesium and by-product yields (silicon, iron, and nickel) will be monitored under various processing conditions.

As positive results begin to flow from the project, Mag One expects to begin a pilot-scale demonstration phase in Q4 of 2019.

The final phase of development will be the design, construction, and start-up of Mag One’s first 5,000 tonne per year primary magnesium metal unit.

Additional units are expected to be brought online to coincide with market demand.

Dr. Douglas Zuliani, president and founder of Tech Magnesium:

“A cost-effective MgO aluminothermic reduction process will be highly disruptive for vehicle light weighting. It will enable the widespread adoption of low carbon-footprint ultra-light magnesium alloy components thereby providing significant weight savings at net costs that are estimated to be highly competitive with current vehicle alloys including aluminum and high alloy steel. I look forward to working with the Mag One team to rapidly develop this game changing technology into a commercial reality.”

Gillian Holcroft, president & CEO of Mag One:

“We are excited to hit the ground running with this first phase of work. I would like to thank the NRC-IRAP for their valuable support in accelerating this Project. The Tech Mag Technology, coupled with our game-changing, serpentinite mine tailings-to-magnesium oxide (MgO) production technology, is aimed at becoming the lowest-cost, greenest primary magnesium metal produced in the world. The team is ready to get to work on charting a path towards commercialization based upon our low-risk modular expansion plan.”

Final thoughts

This NRC-IRAP approval represents significant validation for Mag One’s project.

With the vast majority of magnesium produced by China, there’s a need for a significant new producer on the block.

With a modest market cap of $4.34M, based on its recent dime close, Mag One is a good short list candidate.

END

~ ~ Dirk Diggler

Feature image courtesy of AssignmentPoint.

Full disclosure: Equity Guru does not have a marketing relationship with Mag One.

Leave a Reply