Feeling Gassy?

While a large proportion of natural gas in our atmosphere is man-made, last night’s Taco Bell isn’t to blame. Before we get into it, let’s talk about natural gas and methane, two terms that are commonly used interchangeably. Methane is a colorless, odorless, and flammable greenhouse gas. While natural gas is primarily methane, it also contains ethane, propane, carbon dioxide, and water vapor. Don’t worry, that doesn’t have to make sense, just remember that natural gas contains carbon dioxide (C02).

Natural gas is a fossil energy source that was formed deep beneath the earth’s surface. Over the span of hundreds of millions of years, the remains of plants and animals mixed with sand, silt, and calcium carbonate, creating carbon and hydrogen-rich layers. Eventually, pressure and heat altered some of these layers into the natural energy sources we know today, including coal, oil, and natural gas. With this in mind, we use natural gas as fuel and to make a multitude of materials and chemicals.

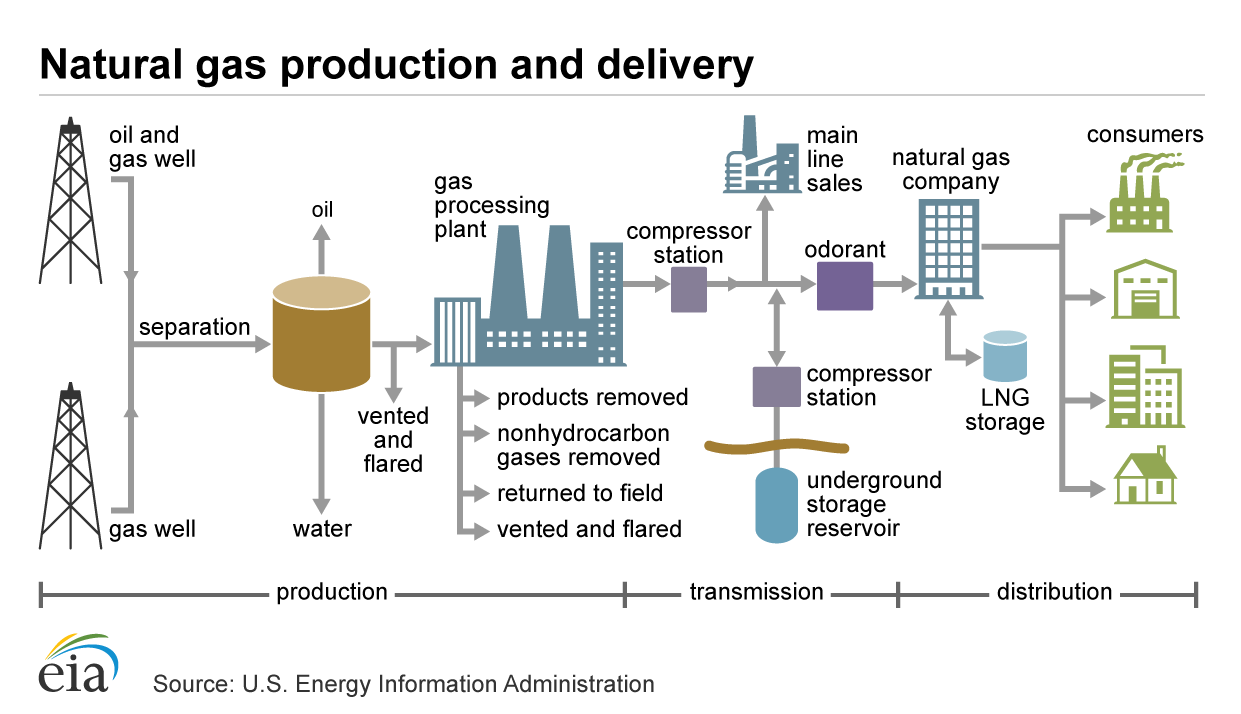

In order to obtain natural gas, one or more production wells are drilled into natural gas-bearing formations. In countries like the United States (US), natural gas is produced from shale and other types of sedimentary rock formations by forcing water, chemicals, and sand down a well under high pressure. This process is referred to as fracturing or fracking, whereby sedimentary rock is broken, allowing natural gas to flow up a well to the surface. Get to the point! In many cases, natural gas is sent through pipelines to underground storage fields or to distribution companies.

However, in places where natural gas pipelines are not available, natural gas may be reinjected into the oil-bearing formation, or it may be vented or burned. If you’d prefer a visual representation of natural gas transportation and processing, refer to the image above, courtesy of the U.S. Energy Information Administration. Similar to collecting all of the Infinity Stones, I have now laid the groundwork to make one singular point. As previously mentioned, carbon dioxide (c02) is a component of natural gas. With this in mind, when we burn natural gas, we release a significant amount of C02 into the atmosphere.

In fact, natural gas combustion accounted for a third of carbon dioxide emissions from the US power sector in 2018, according to the Center for Climate and Energy Solutions. To make matters worse, since 2005, annual consumption of natural gas in the US has increased by nearly 41%, making natural gas the largest source of US electric power generation.

Remember when I said natural gas was primarily comprised of menthane? Research indicates that we have underestimated the methane impacts of possible fuel extractions by up to 40%. Keep in mind, methane is exceptional at absorbing heat. On a 20-year timescale, a methane molecule is approximately 90 times more effective at trapping heat in the atmosphere than a molecule of carbon dioxide.

Biogas for Dummies

A bit of a jump in subject matter here but bear with me. Biogas is a mixture of gases, primarily consisting of methane and carbon dioxide, produced from raw materials including agricultural waste, manure, municipal waste, plant material, sewage, green waste, and food waste. More importantly, biogas is a versatile renewable energy source that can be used as fuel. How is this any different than natural gas? As defined by National Geographic, there are four major types of nonrenewable energy resources:

- oil

- natural gas

- coal

- nuclear energy

That being said, we are currently dependent on nonrenewable sources as our primary source of energy. Unfortunately, around 80% of the total amount of energy used globally each year comes from fossil fuels. Keep in mind, fossil fuels accounted for 74% of total US greenhouse gas (GHG) emissions. Getting back to your question, the most notable difference between natural gas and biogas is that natural gas is a nonrenewable energy source. On the contrary, biogas is a clean, non-polluting, renewable source of energy.

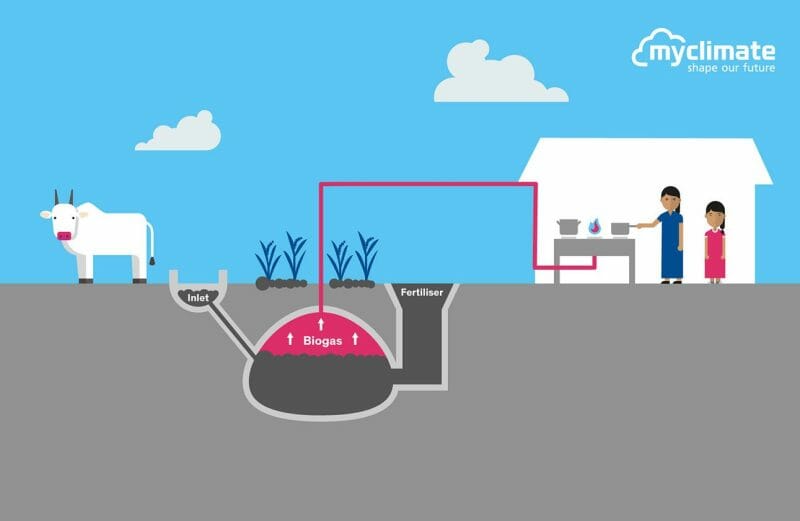

Furthermore, no combustion takes place when creating biogas, meaning there are zero emissions of greenhouse gasses into the atmosphere. With this in mind, biogas generation plays a pivotal role in reducing our reliance on fossil fuels. Additionally, unlike other types of renewable energies, biogas does not require energy for the generation process. On a smaller scale, the technology used to produce biogas is relatively cheap, easy to set up, and requires little investment. In a household, biodigesters can be used to convert kitchen waste and animal manure into energy. On the other hand, utilizing biogas upgrading systems, large plants are able to compress biogas to achieve the quality of natural gas needed to power automobiles.

Greenlane Renewables Inc.

- $190.677M Market Capitalization

Now that I have subjected you to an entire novel related to natural gas, methane, and biogas, let’s talk about a company with skin in the game. Greenlane Renewables Inc. (GRN.T) is a leading global provider of biogas upgrading systems that are helping decarbonize natural gas. With this in mind, Greenlane is cleaning up two of the largest and most challenging sectors to decarbonize, including the natural gas grid and transportation sector. Greenlane’s solutions create clean, low-carbon renewable gas (RNG), suitable for injection into the natural gas grid and for direct use as vehicle fuel.

More specifically, Greenlane’s biogas upgrading plants marketed and sold under the Greenlane Biogas™ brand, remove impurities and separate carbon dioxide from biomethane in the raw gas created from organic waste at landfills, wastewater treatment plants, farms, and food waste facilities. In total, Greenlane has over 125 systems throughout 19 countries and more than 30 years of experience under its belt. Keep in mind, Greenlane is the only biogas upgrading company to offer multiple core technologies:

Water Wash:

- the most deployed biogas upgrading technology in the world

- uses counter-flow water to scrub away impurities, without the need for chemicals or heat

- purified methane is then dehydrated, creating pure, dry RNG

- water is cleaned and reused in a closed-loop

Pressure Swing Adsorption (PSA):

- hydrogen sulfide is removed first

- biogas is then chilled and dehydrated

- adsorbent media traps C02, nitrogen, oxygen, and any remaining moisture

- this allows menthane to pass through as clear and dry RNG

- afterward, adsorbent media is regenerated and reused

Membrane Separation

- porous membranes used to separate C02 from methane via permeation

- as biogas passes through, selective membranes allow for smaller C02 molecules to pass through

- able to remove both C02 and oxygen (O2) together

- offers reliable performance and a biomethane recovery rate typically over 99%

Biogas Upgrading

Biogas upgrading systems cleanse contaminants from raw biogas and separate C02 from biomethane, compressing the resulting gas. This gas can then be used directly as a clean, high-purity, low-carbon fuel that is renewable and meets specific pipeline or transportation application requirements. To simplify things here’s a very loose analogy that came to mind after putting my cup of coffee down. Generated biogas is similar to ground coffee in the sense that we aren’t going to consume raw coffee grinds. At least I hope not, but you do you. With this in mind, biogas upgrading is like a Keurig coffee machine that processes coffee grinds into a drinkable beverage. In the case of biogas upgrading, biomethane is the end result.

Biomethane is essentially biogas from which C02, hydrogen sulfide, and water have been removed. As a result, biomethane has the same characteristics as natural gas and can be injected into the natural gas grid. Ultimately, biomethane is a renewable natural gas (RNG) that is interchangeable with natural gas in the distribution network or when used directly in vehicles, removing the carbon footprint and providing a green-energy alternative. In short, biomethane is pretty dandy and provides a green alternative to natural gasses, which currently pump our atmosphere with menthane.

Latest News

Most recently, on January 4, 2022, Greenlane announced that, through its wholly-owned subsidiary Greenlane Biogas North America Ltd., it has signed two new biogas upgrading system supply contracts valued in total at CAD$7.1 million for separate renewable natural gas (RNG) projects in the US and Brazil. Order fulfillment by Greenlane for both projects will commence immediately. With regards to the Company’s project in the US, Greenlane has been awarded a contract for the supply of a biogas upgrading system for a dairy farm RNG project in the State of Nebraska.

“Dairy-derived RNG is highly carbon-negative providing one of the most impactful ways to achieve deep decarbonization and reach net-zero emissions targets…For this reason, it continues to be one of the most dynamic and fastest-growing segments of the market,” commented Brad Douville, President and CEO of Greenlane.

To be more specific, Greenlane will supply its Pressure Swing Adsorption (PSA) system for upgrading biogas generated from anaerobic digestion of dairy cow manure into carbon-negative RNG suitable for injection into the local pipeline network. As for Greenlane’s second project, the Company has won a contract for a landfill gas-to-RNG project in Brazil with one of the country’s largest landfill operators, Orizon Volarizacao de Residuos (Orizon). For this project, Greenlane will supply its water wash system to upgrade the landfill’s gas to low carbon RNG.

“This new project for Greenlane marks the sixth system supply contract we have won in a country that we believe has significant upside potential for biogas upgrading, including landfill gas-to-RNG, sugarcane production waste, and other types of upgrading projects…

Although Brazil’s RNG industry is in the early stages of development, Greenlane has been an early mover and market share leader in the country, having sold 67% of the commercial-scale biogas upgrading systems in the country,” continued Brad Douville, President.

Additionally, on December 23, 2021, Greenlane announced that Greenlane Biogas North America Ltd. has been awarded a $12.1 million contract by FortisBC Energy Inc. (FortisBC). Through this contract, the Company will supply a biogas upgrading system for a new project at the Vancouver landfill in British Columbia, Canada, with order fulfillment expected to commence immediately. Similar to the Company’s most recent contracts, Greenlane will supply its two-stage pressure swing PSA system to upgrade the landfill gas to clean, low carbon RNG for direct injection into FortisBC’s regional natural gas pipeline.

“Increasing the amount of RNG supply in our natural gas delivery system is an important driver in helping our customers reduce their greenhouse gas emissions by 30 percent by 2030, and this project will meaningfully increase that RNG supply…Greenlane’s expertise and experience in biogas upgrading is a welcome addition to this exciting project,” said David Bennett, Director of Renewable Gas and Low Carbon Fuels with FortisBC.

For context, FortisBC is a regulated utility focused on providing safe and reliable energy, including natural gas, renewable gas, propane, and thermal energy solutions. The company serves approximately 1.2 million British Columbians and operates roughly 50,182 kilometers of natural gas transmission and distribution pipelines. With this in mind, Greenlane’s PSA biogas upgrading system will have a significant impact on FortisBC’s decarbonization of its natural gas supply.

Financials

According to Greenlane’s Q3 2021 Financial Results, the Company had cash and cash equivalents of CAD$35.6 million and no debt, other than payables and bonding resulting from normal course operations, as of September 30, 2021. Additionally, Greenlane reported a record revenue of CAD$13.4 million, indicating an increase of 107% over the CAD$6.5 million reported in Q3 2020. In total, the Company achieved a gross profit of CAD$3.1 million, a gross margin of CAD$3.4 million, and a net income of CAD$100,000.

In addition to reporting record revenue, Greenlane also reported a record sales order backlog of CAD$47.1 million as of September 30, 2021. Furthermore, the Company’s sales pipeline was valued at more than CAD$850 million as of September 30, 2021. Aside from the contracts outlines in this article thus far, Greenlane previously announced new contract wins totaling CAD$18.9 million for the supply of five biogas upgrading systems. Through the first contract, Greenlane will supply its membrane separation biogas upgrading system for a project owned by an international energy company in the US.

Subsequently, Greenlane will supply two PSA biogas upgrading systems for dairy farm RNG projects in the States of Wisconsin and New York, developed and owned by a leader in the waste-to-energy industry. Lastly, Greenlane will supply two PSA upgrading systems for Green Impact Partners in Colorado. Following contract signing, Greenlane expected to begin order fulfillment immediately. Before today, I didn’t know the first thing about biogas, let alone biomethane. By no means am I now an expert, but I am still hopeful for a company like Greenlane nonetheless.

My personal sentiment isn’t worth diddly-squat, however, the Global Methane Pledge signed by more than 100 countries at the COP26 UN Climate Change Conference bodes very well for a company like Greenlane. Keep in mind, the multitude of countries that signed this pledge account for 70% of global GDP. Collectively, these countries have pledged to reduce methane emissions by 30% by 2030 from 2020 levels. It is also worth noting that, as outlined in a COP26 announcement, over $130 trillion of private finance is now committed to science-based net-zero targets and near-term milestones.

Greenlane’s share price closed at $1.29 on January 7, 2022.

For more on sustainability, check out my Substack!

Leave a Reply